1. Understanding Partial Discharge (PD)

Partial Discharge (PD) refers to a phenomenon where, under high voltage conditions, discharge occurs in a localized region of an insulating material, while the remaining parts of the material maintain their insulation properties. Specifically, when there is a voltage difference between two or more insulating materials, if an air gap, crack, or impurity exists in the insulation, the electric field strength in that area may exceed the material’s withstand capacity, leading to partial discharge. This partial discharge is an early signal of insulation degradation, and if it continues over time, it can lead to insulation failure, resulting in product malfunction or failure.

2. Common Causes of Partial Discharge in Power Components

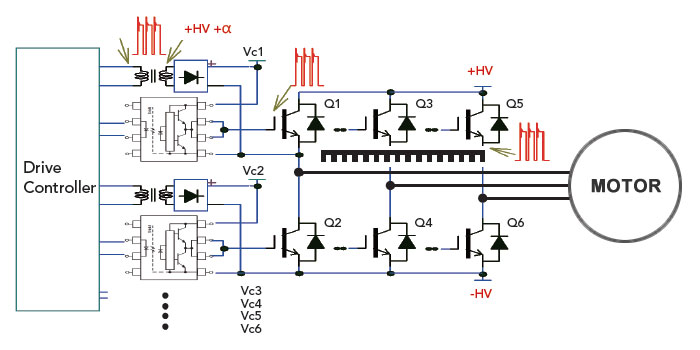

Power components, especially IGBT modules used in high-power or high-current applications, are commonly subjected to the risk of partial discharge. Some common causes are:

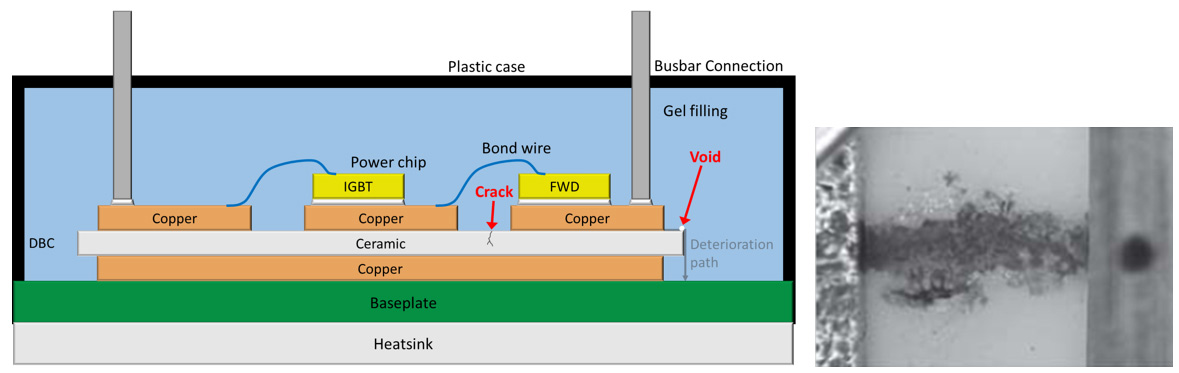

- Insulation Material Quality Issues: Air gaps, cracks, or impurities in the insulation can initiate partial discharge.

- High Voltage Differences: In IGBT modules, high voltage differences can occur between the gate and collector or between the module and the heat sink, increasing the likelihood of partial discharge.

- Deterioration of Operating Environment: Over prolonged high voltage operation, partial discharge can progressively degrade the insulation material.

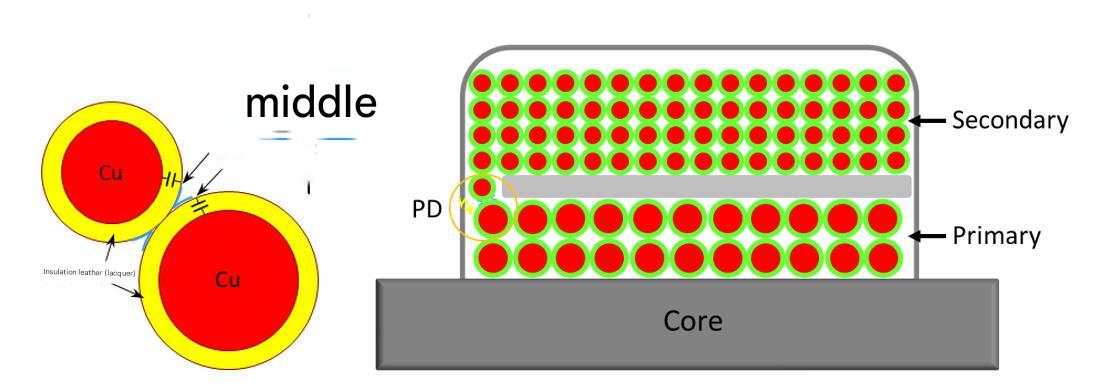

- Transformer Design Issues: When the primary and secondary coils of a transformer are too close together, partial discharge may occur between the coils, leading to electrical interference and insulation failure.

3. Hazards of Partial Discharge

Although partial discharge may not immediately cause failure, its prolonged existence can seriously affect the stability and lifespan of electrical components. The main hazards include:

- Insulation Material Degradation: Partial discharge causes chemical reactions in the insulation material, gradually leading to carbonization or aging, resulting in loss of insulation properties.

- Performance Degradation: The electromagnetic interference (EMI) generated during partial discharge can disrupt digital control circuits or other sensitive circuits, causing malfunction or failure.

- Severe Equipment Failure: If partial discharge continues over time, it can lead to short circuits, breakdowns, and even catastrophic events such as fires or explosions.

4. How to Reduce Partial Discharge in Power Components

To reduce the risk of partial discharge in power components, several approaches can be taken:

a. Improve Design

- Select High-Quality Insulation Materials: Choose high-quality insulation materials that can withstand high voltages and avoid air gaps and cracks.

- Optimize Insulation Structure: Ensure the internal insulation structure of the components is designed properly to avoid uneven voltage distribution and areas of high electric field strength.

- Increase Insulation Layer Thickness: Increasing the thickness of insulation layers can enhance the voltage withstand capacity, reducing the likelihood of partial discharge.

b. Increase Clearance Distances

- Increase Component Spacing: In power module designs, ensure there is enough clearance between electrical components to prevent partial discharge.

- Optimize Transformer Structure: For transformers, increase the distance between the primary and secondary coils to prevent partial discharge caused by too small an air gap.

c. Use Advanced Detection Technology

- Partial Discharge Testing: Use advanced equipment such as the Chroma 19501 Partial Discharge Tester to conduct partial discharge tests. By applying a voltage slightly higher than the rated operating voltage, partial discharge can be detected, ensuring no sustained partial discharge occurs under normal operating conditions. This kind of testing helps identify potential insulation issues before they worsen.

- Regular Testing and Monitoring: For long-term operating high-power devices, it is essential to perform regular partial discharge tests to ensure reliability and safety.

d. Enhance Manufacturing Processes

- Ensure Material Purity and Consistency: During manufacturing, use high-purity insulation materials and strictly control the production process to minimize the presence of bubbles, cracks, and other defects in the material.

- Improve Assembly Processes: Ensure that all connections and insulation materials are defect-free during component assembly to prevent partial discharge caused by improper assembly.

e. Perform Appropriate Voltage Testing

- Follow Standard Testing Methods: Perform partial discharge testing according to IEC 60270 standards, applying a test voltage that is 1.875 times the rated voltage. During the test, the partial discharge quantity should be less than a specified charge amount (e.g., 5pC or 10pC), ensuring that no continuous partial discharge occurs during the product’s long-term use.

5. Detection and Solutions for Partial Discharge

Effective detection of partial discharge is essential to ensure the long-term reliable operation of power components. Using high-performance equipment such as the Chroma 19501 Partial Discharge Tester can detect insulation quality issues in high-voltage components. This testing equipment not only detects potential partial discharge problems but also helps assess the risk of insulation degradation, allowing for timely maintenance and intervention.

- Chroma 19501 Partial Discharge Tester: This device meets the requirements of IEC 60270-1 and can perform AC withstand voltage tests (up to 5kVac) and partial discharge measurements (1pC~6,000pC@3nF). It effectively detects insulation quality abnormalities in high-voltage power components, ensuring long-term operational reliability and quality.

6. Conclusion

Partial discharge is an early indication of insulation quality issues in power components, posing a serious threat to the reliability and safety of the equipment over time. By optimizing design, using high-quality insulation materials, conducting regular partial discharge tests, and improving manufacturing processes, the risk of partial discharge can be effectively reduced. Additionally, employing specialized testing equipment such as the Chroma 19501 Partial Discharge Tester is critical to ensuring the long-term stable operation of power components, maintaining their quality and reliability over time.

More Articles: